Image 1 of 9

Image 1 of 9

Image 2 of 9

Image 2 of 9

Image 3 of 9

Image 3 of 9

Image 4 of 9

Image 4 of 9

Image 5 of 9

Image 5 of 9

Image 6 of 9

Image 6 of 9

Image 7 of 9

Image 7 of 9

Image 8 of 9

Image 8 of 9

Image 9 of 9

Image 9 of 9

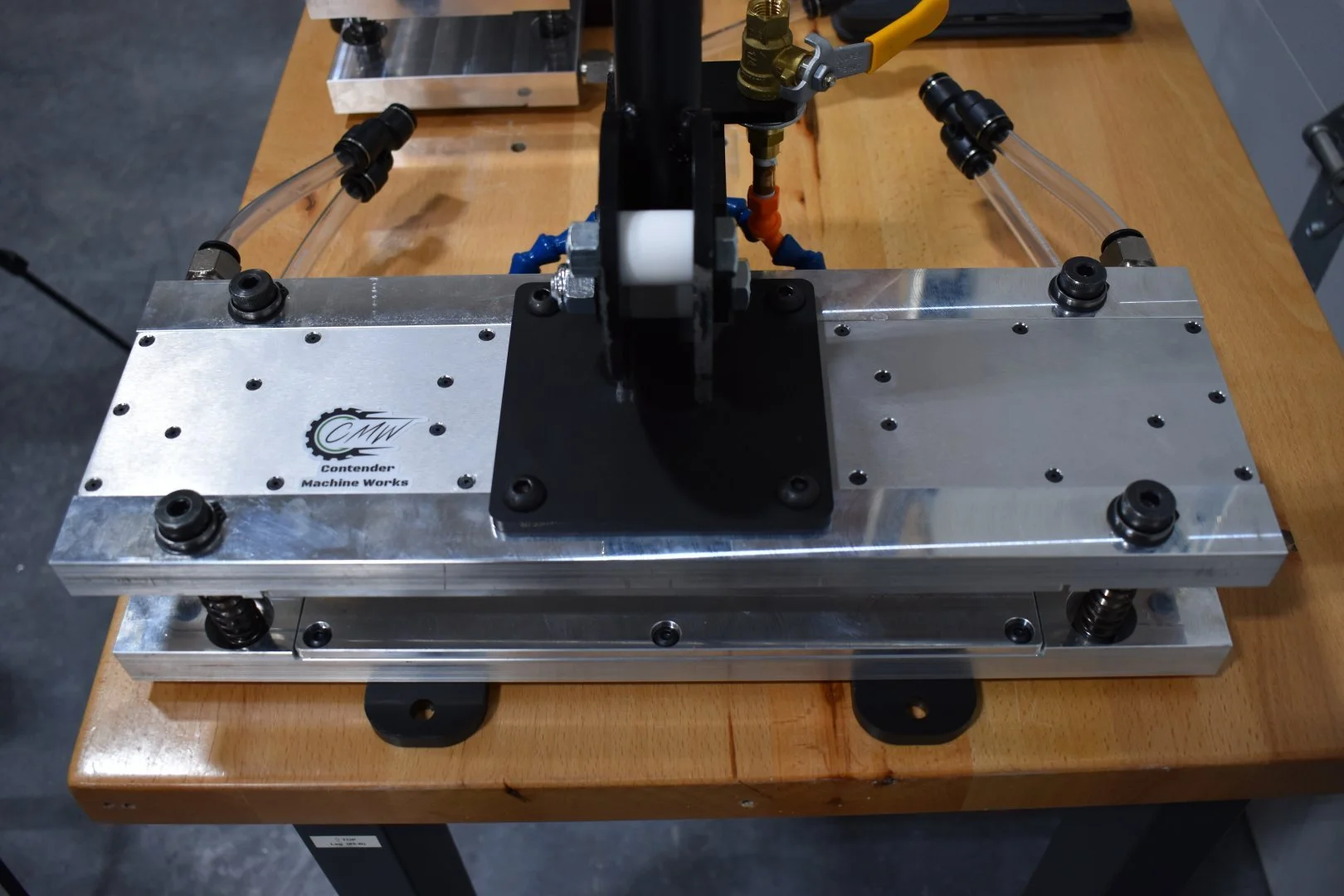

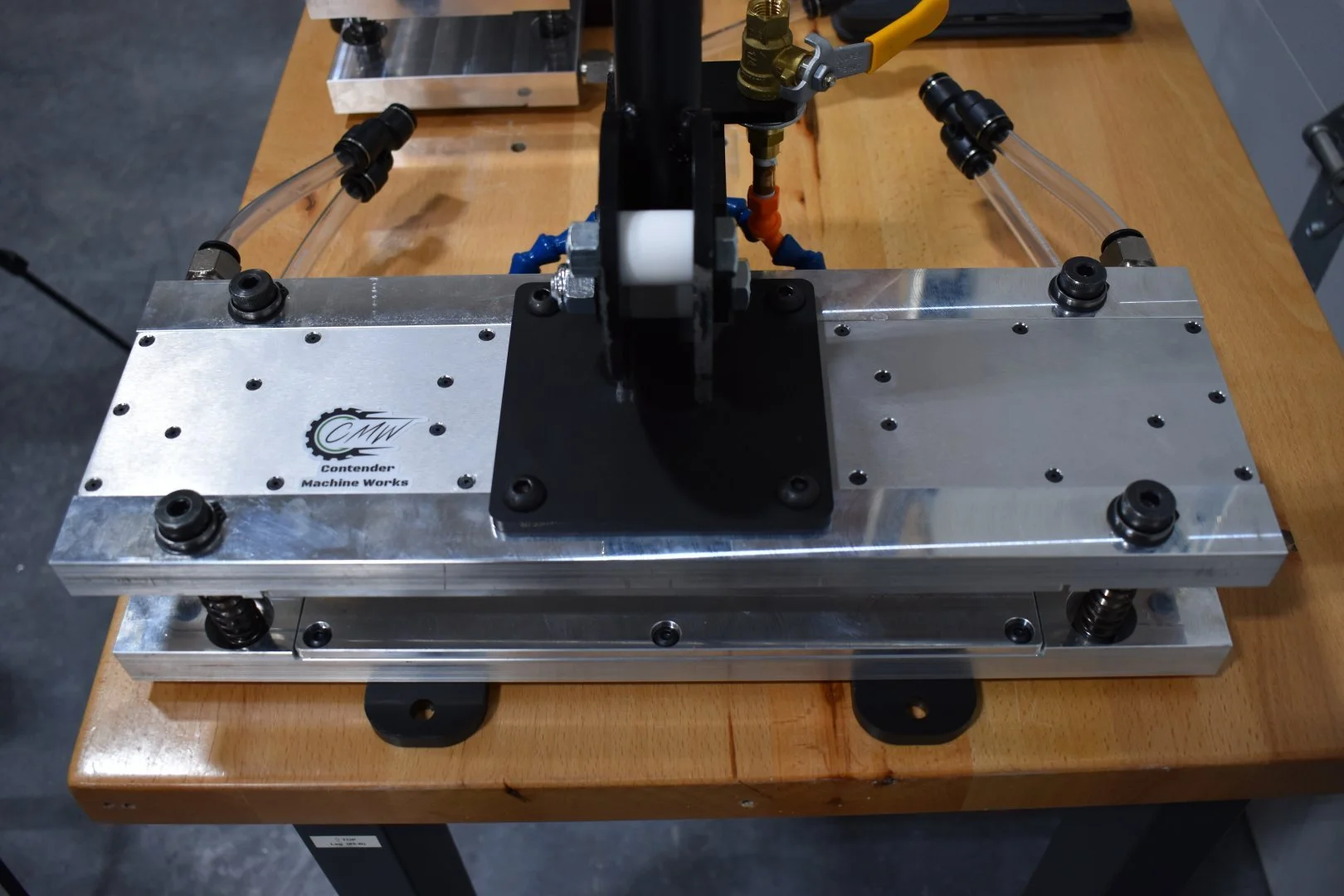

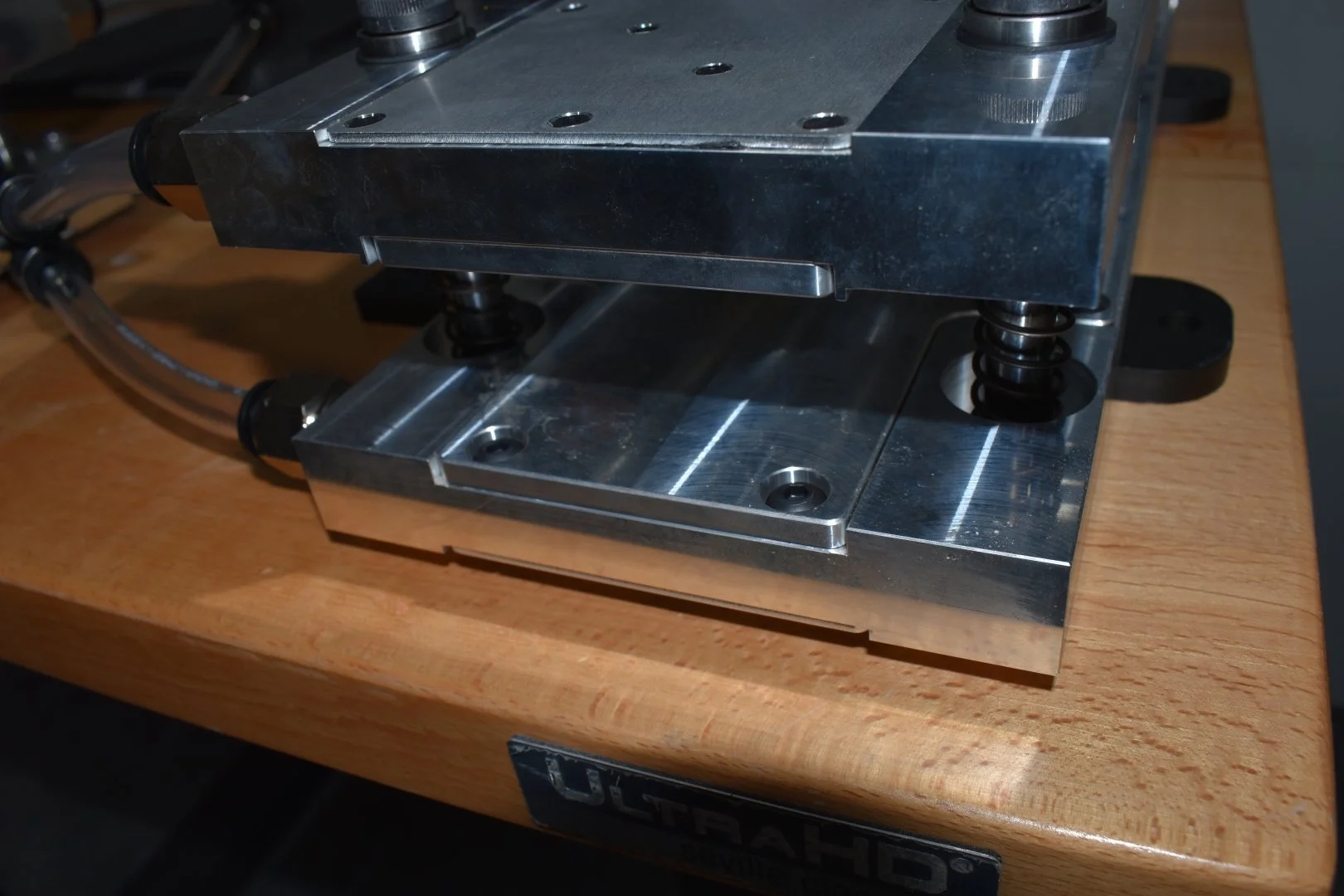

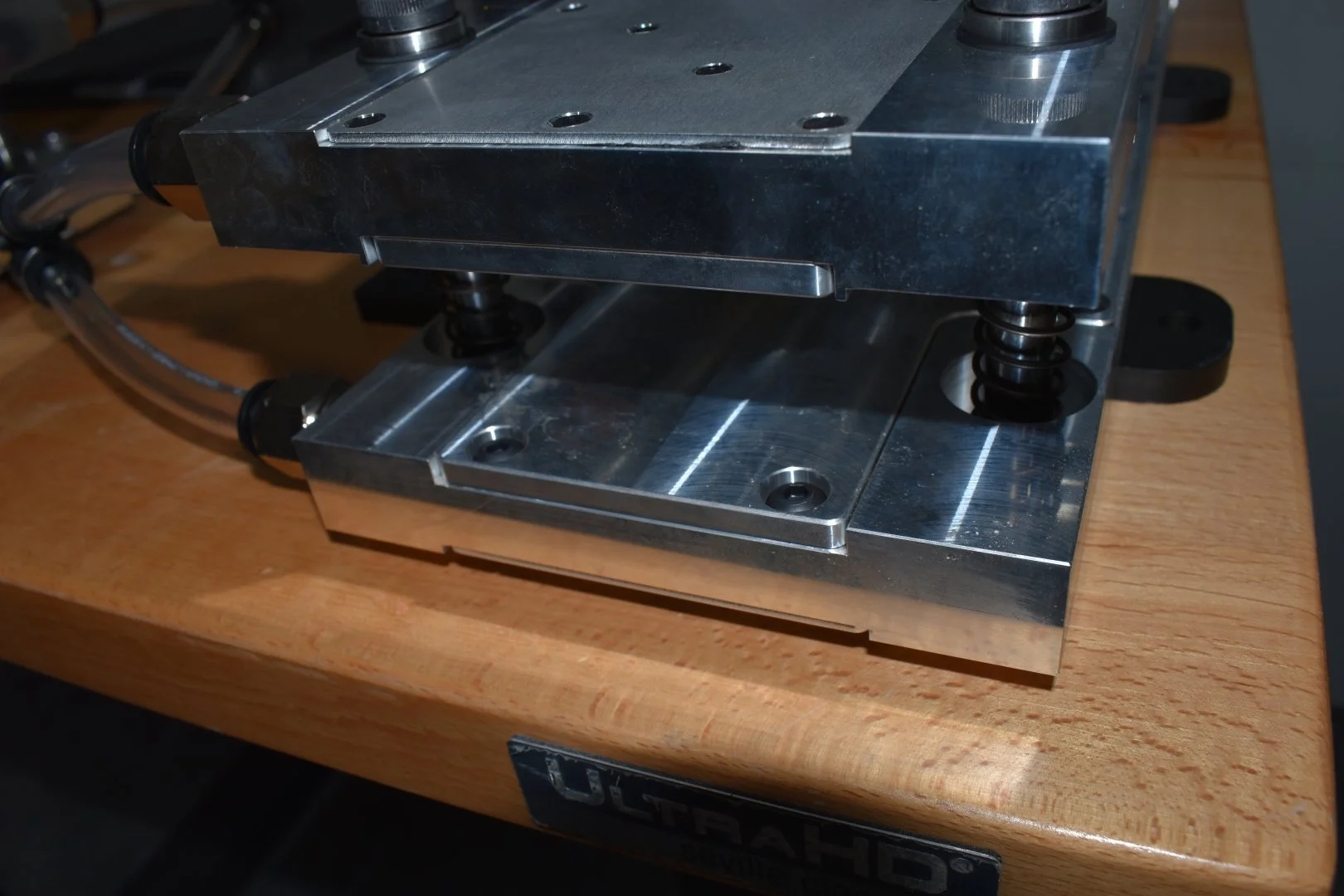

Quench Plate Press

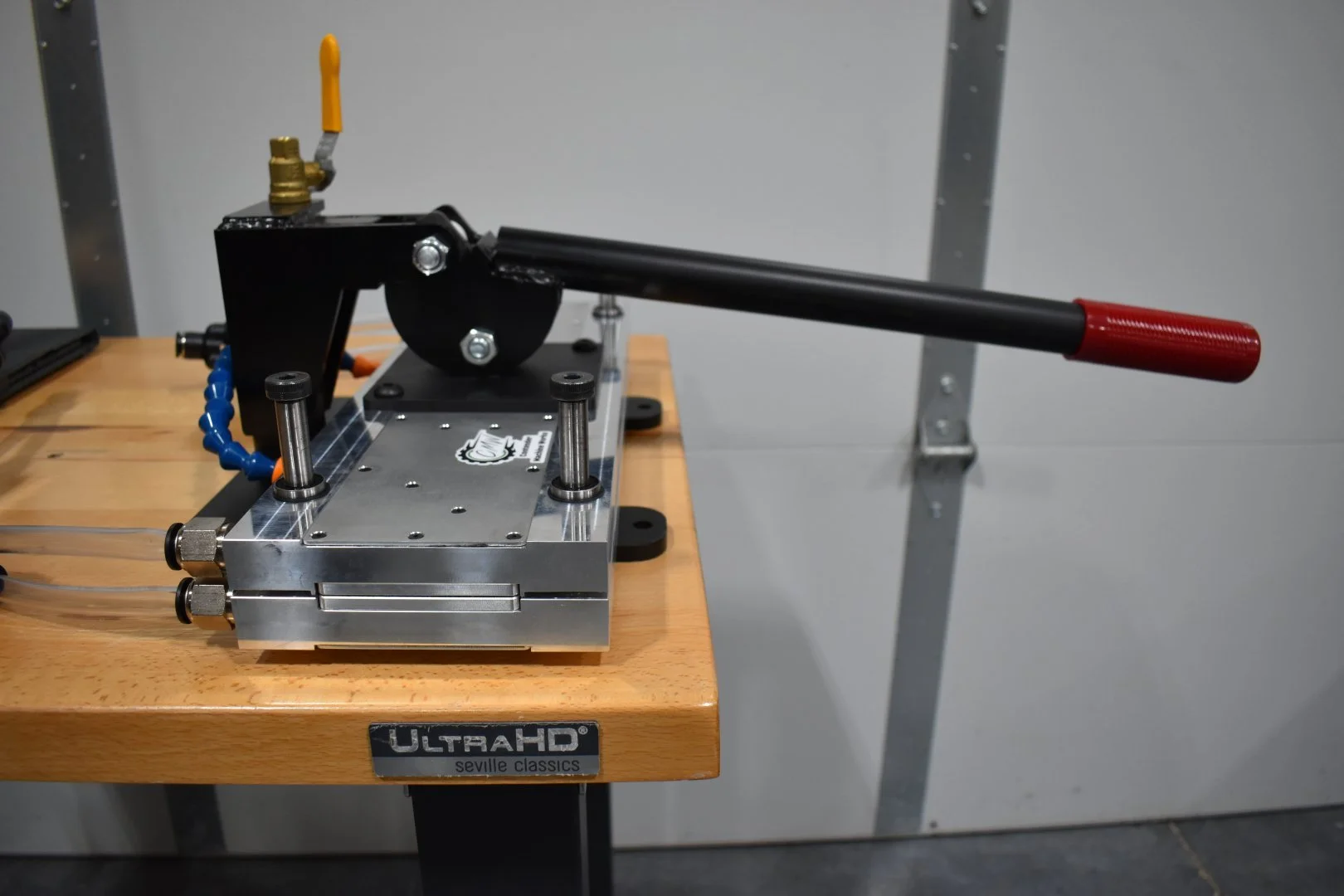

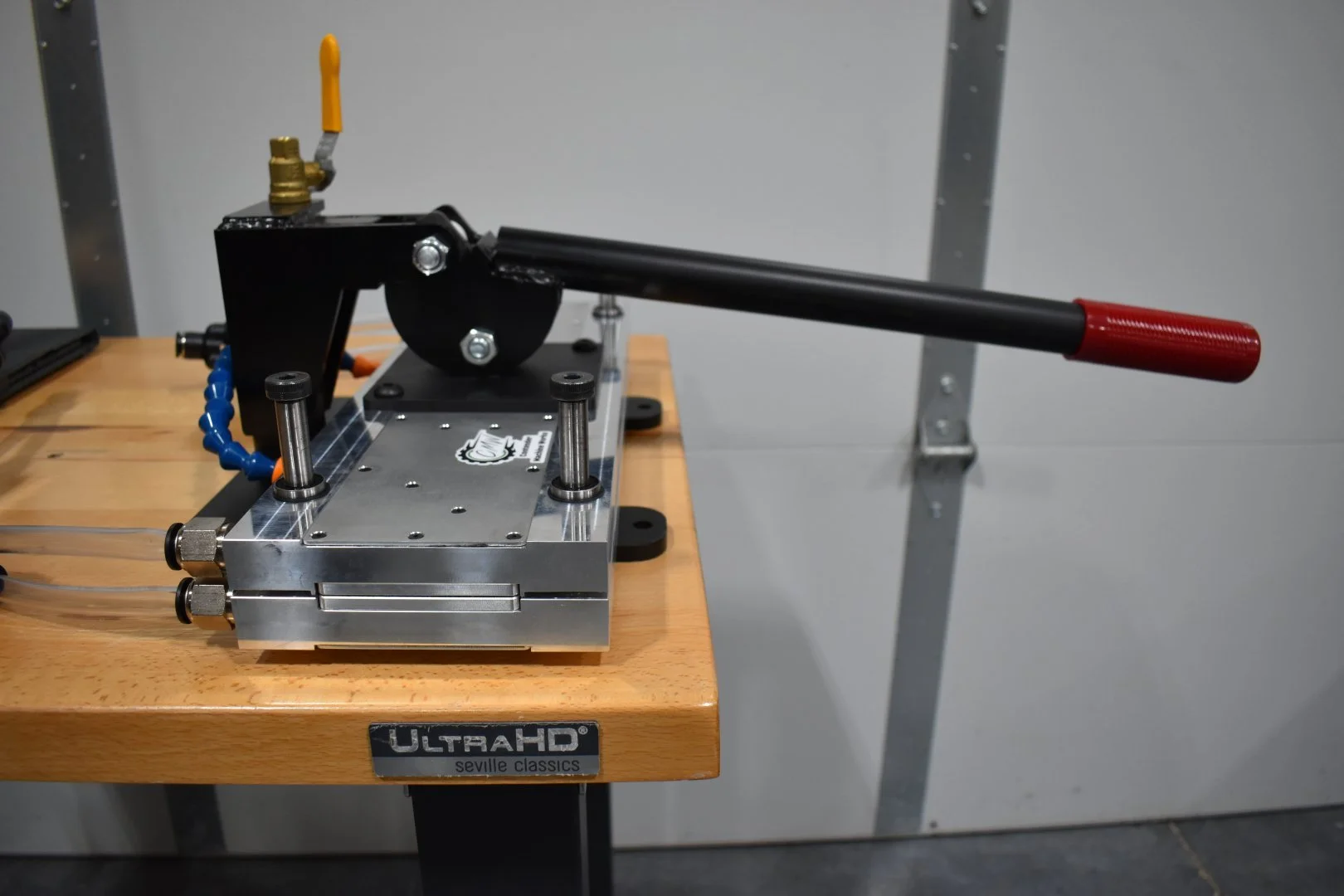

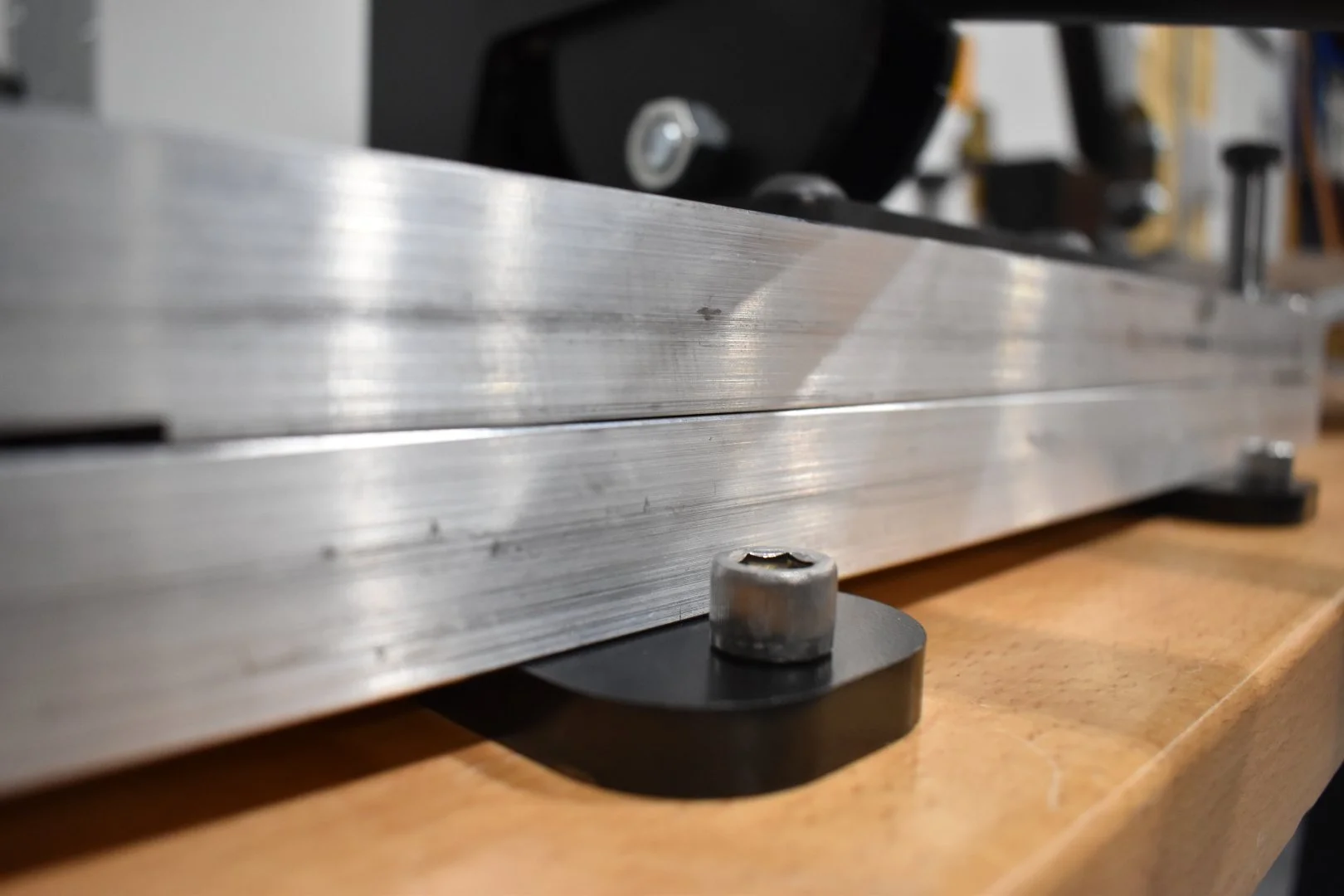

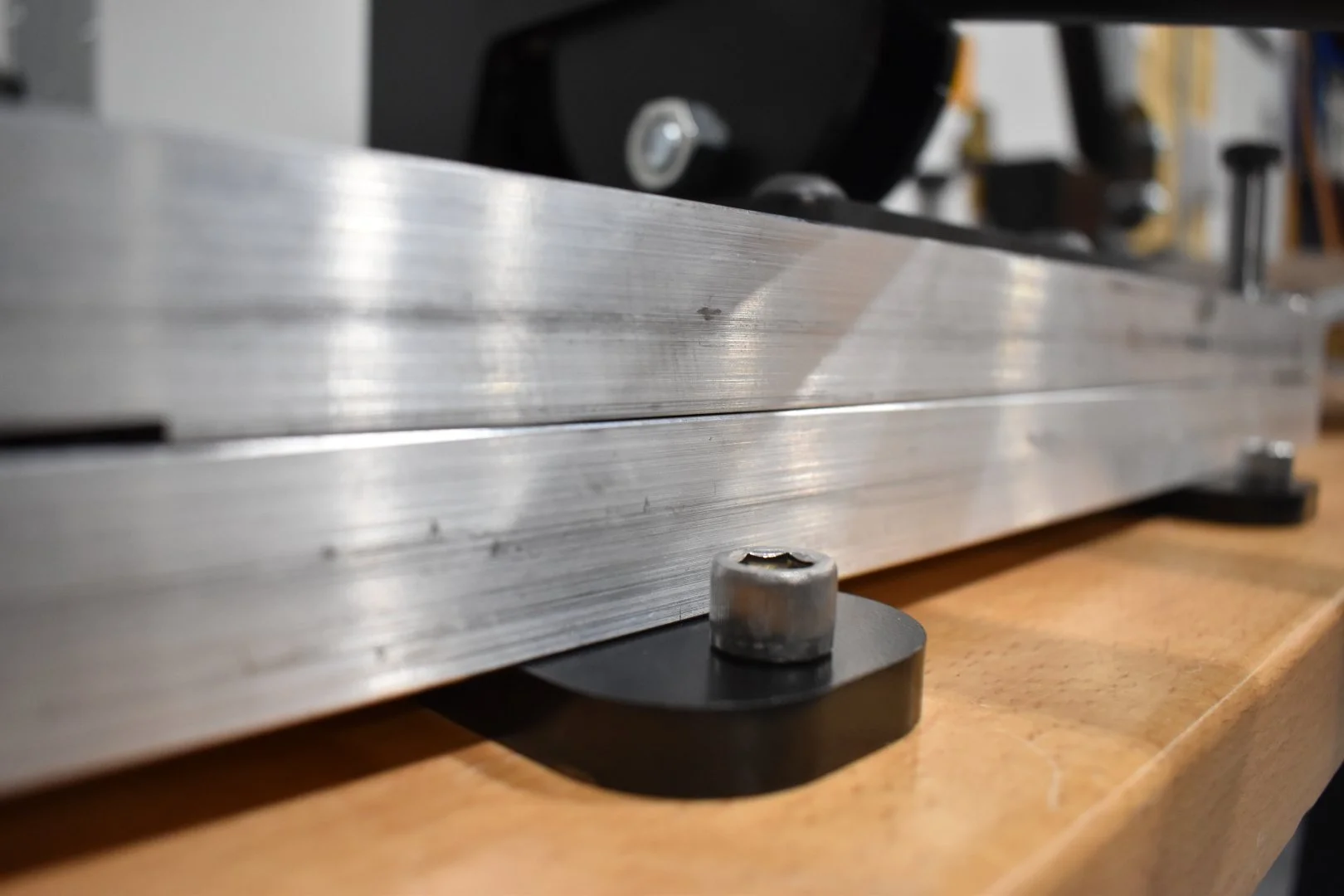

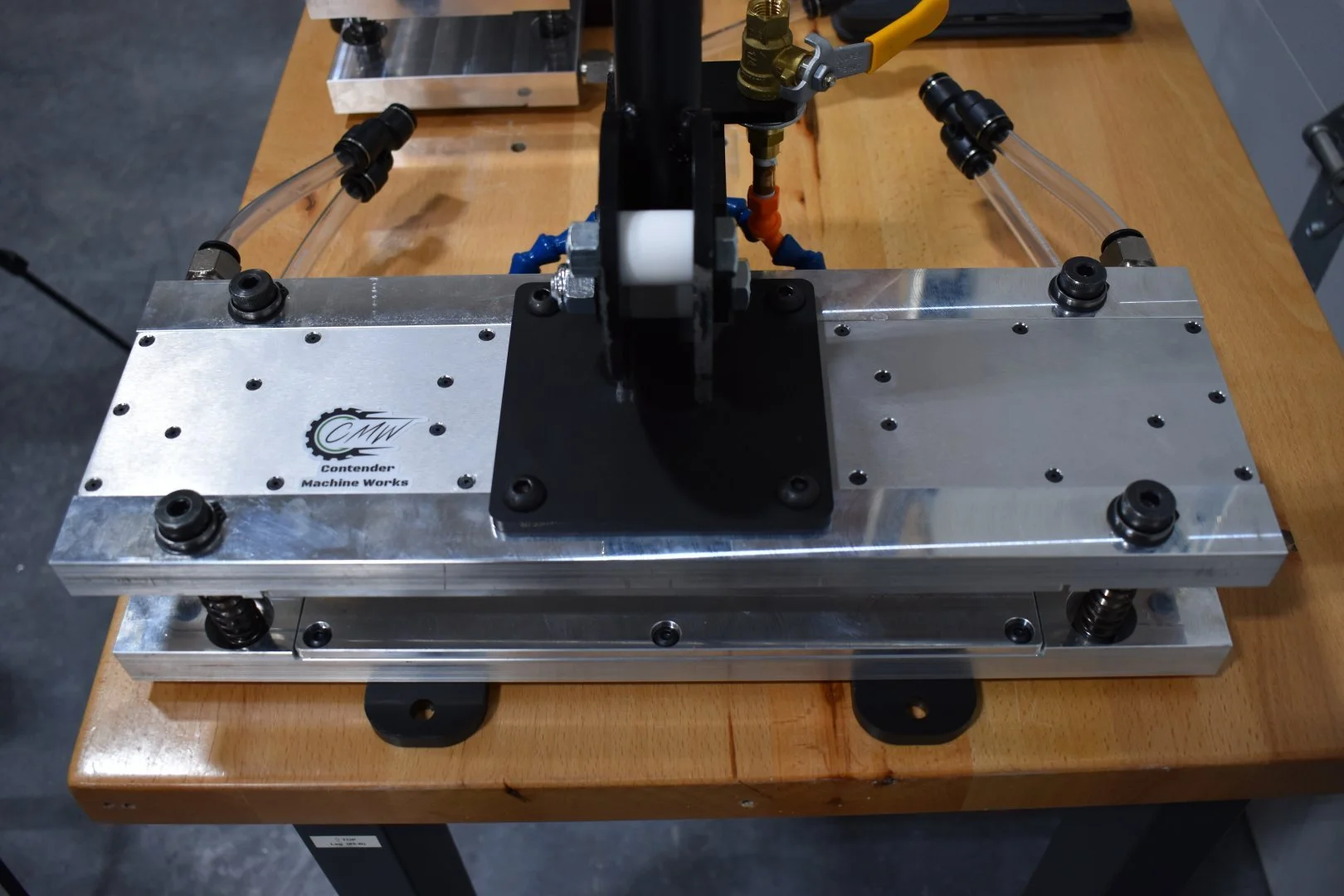

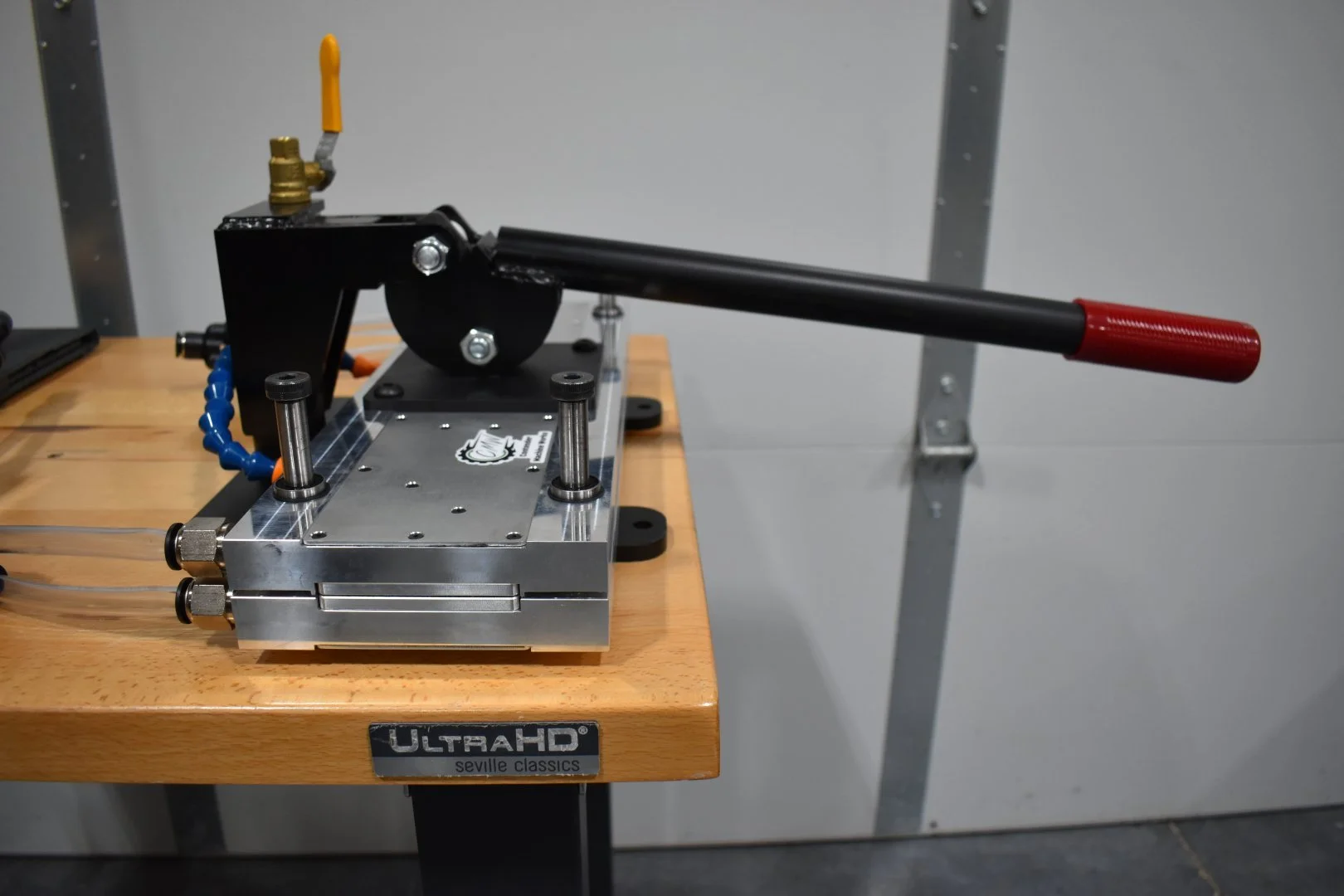

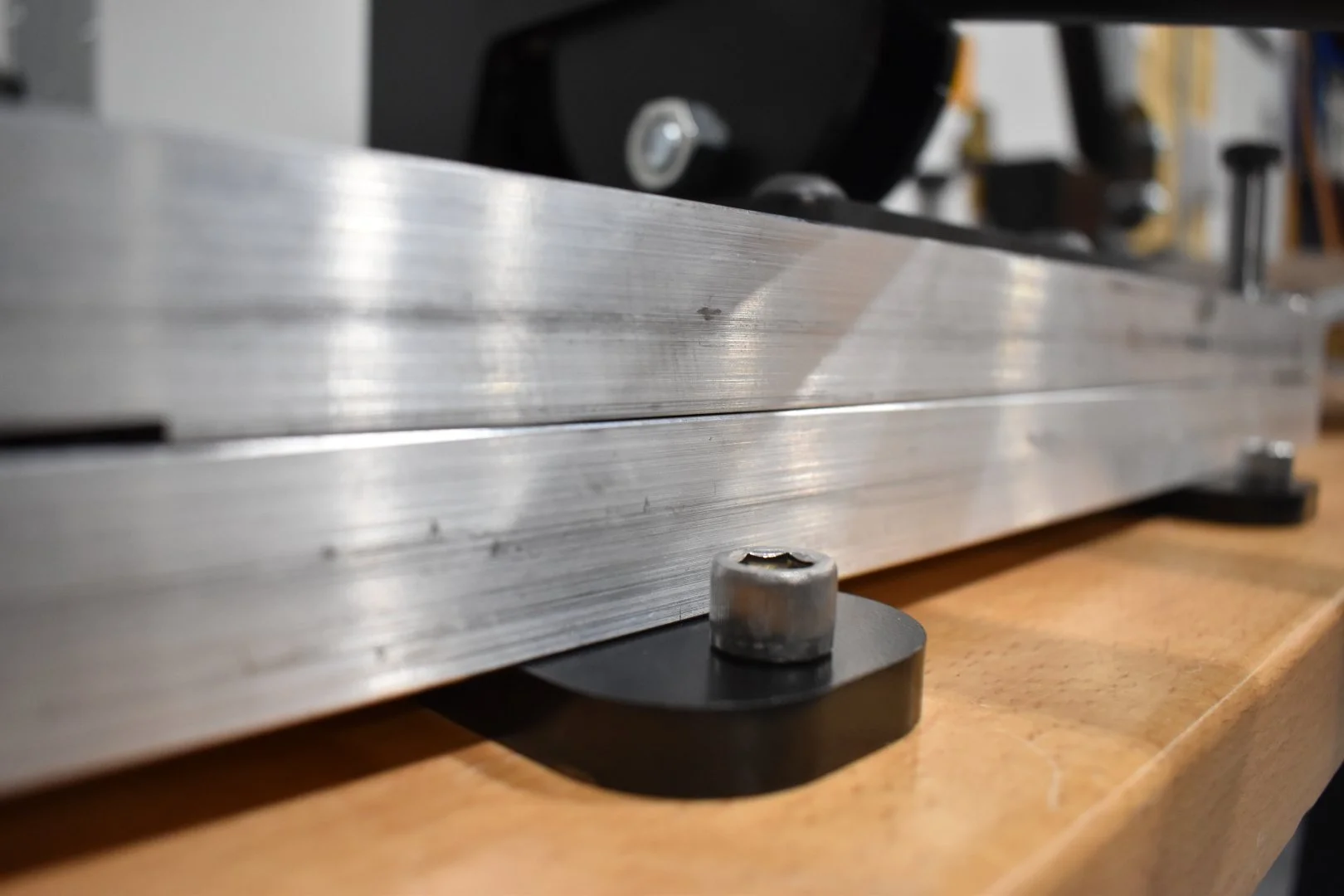

The Contender Machine Works quench plate press is the easy solution for heat treating your air hardening steels. The press features machined 1 inch thick aluminum plates that ride on linear bearings for a smooth and accurate plate quench.

Both 15.5- and 18-inch-long plates available. Please inquire about custom plate sizes.

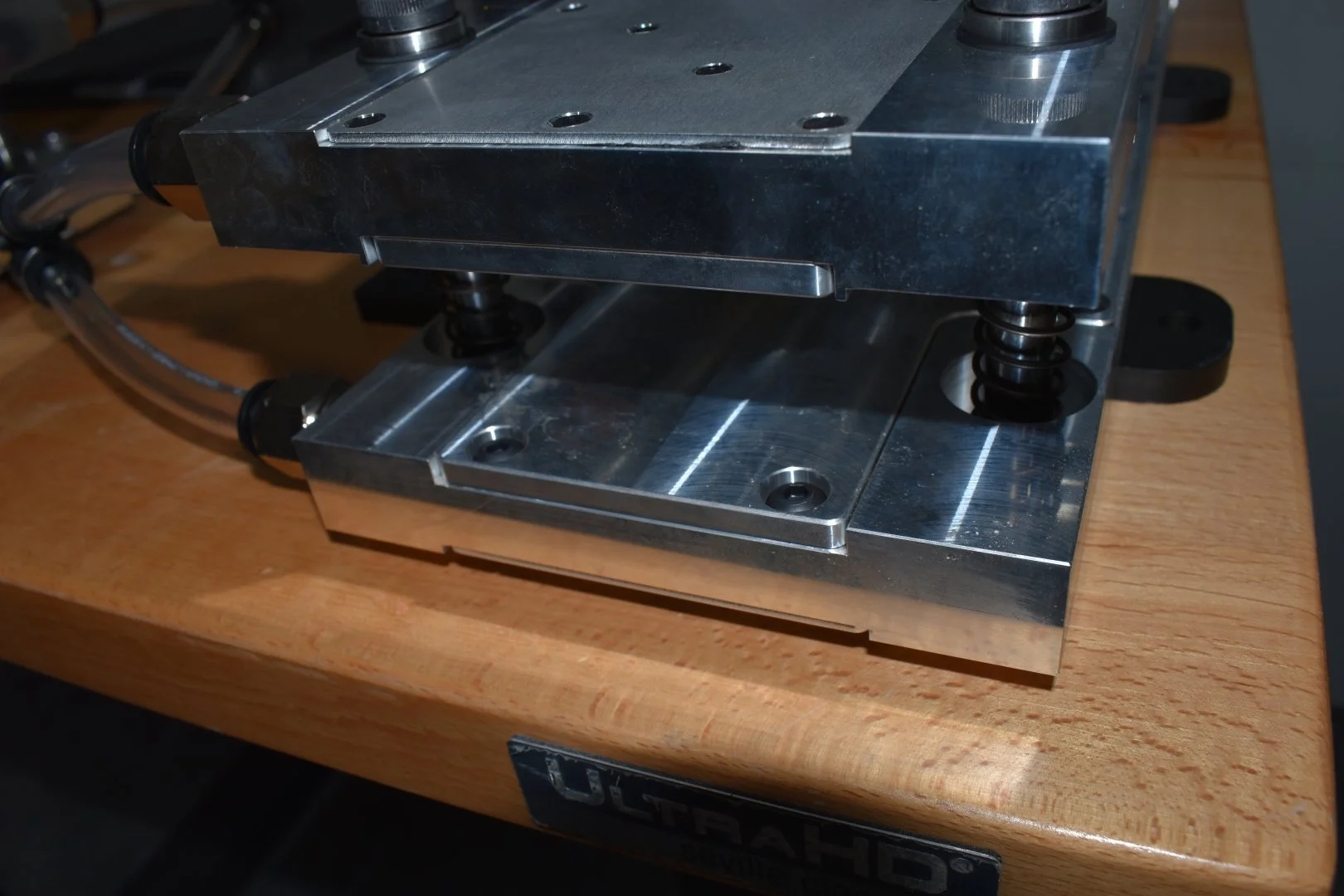

Water jackets running through both plates provide constant cooling to keep the plates a consistent temperature. This is key to a consistent and accurate quench when heat treating a batch of blades.

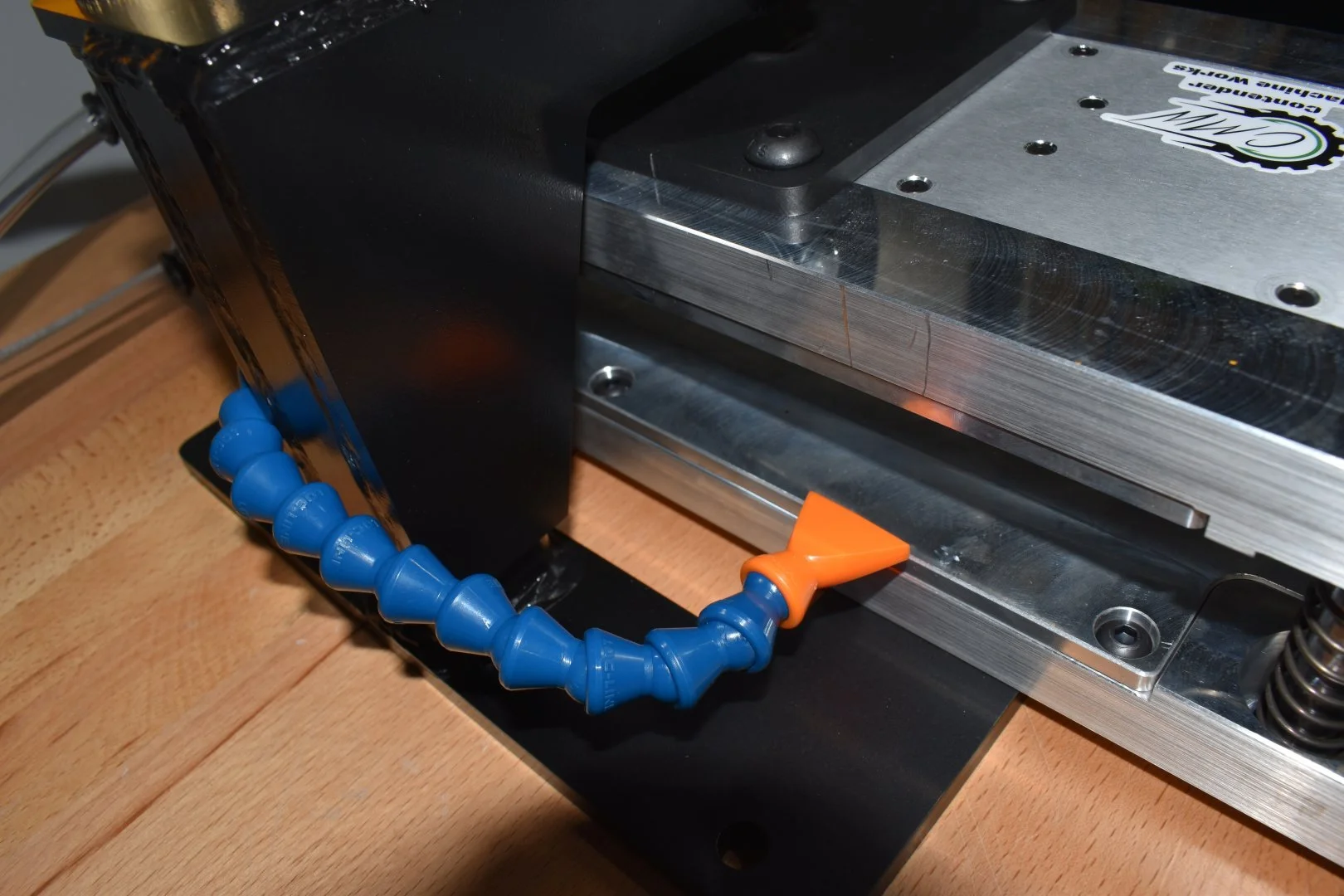

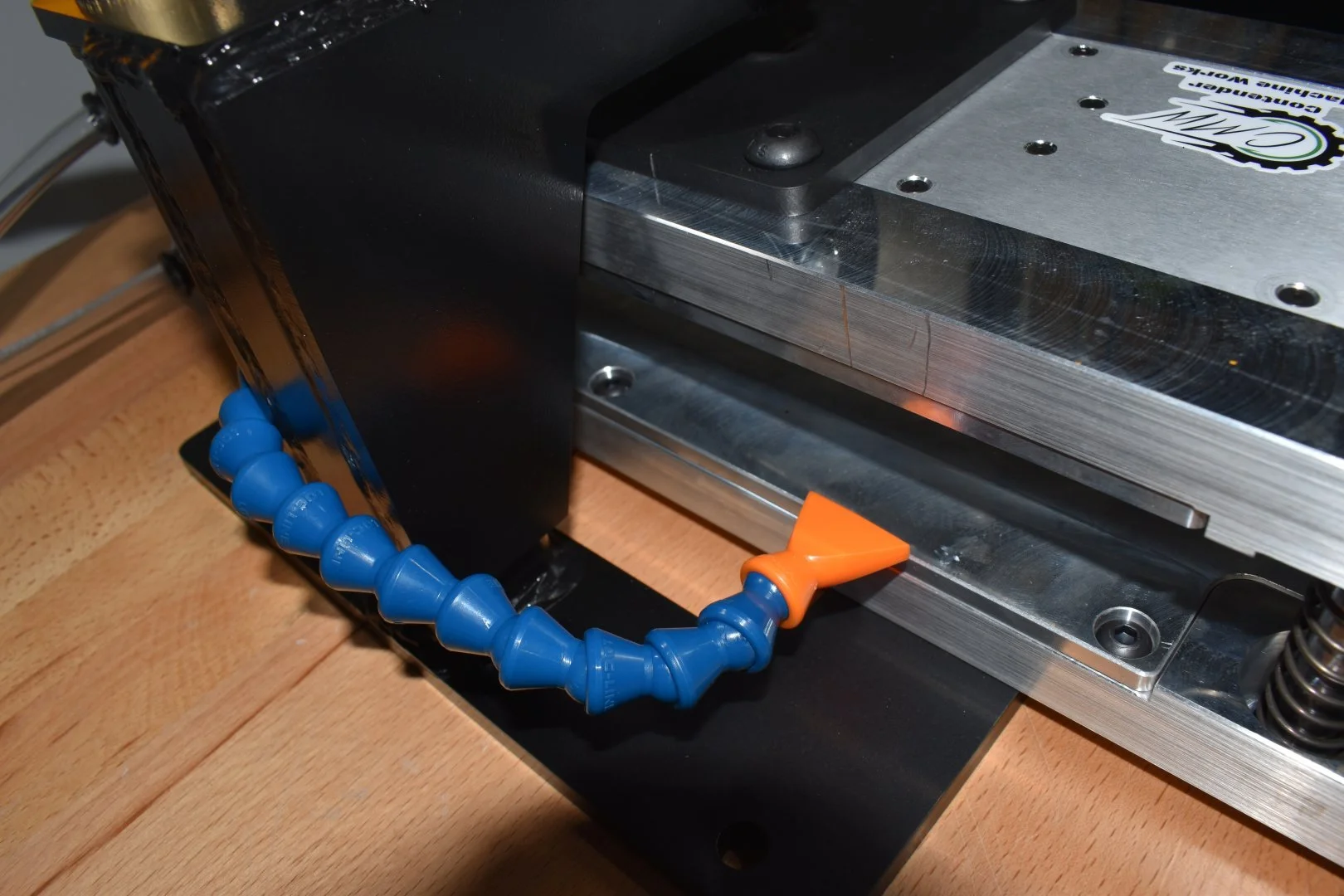

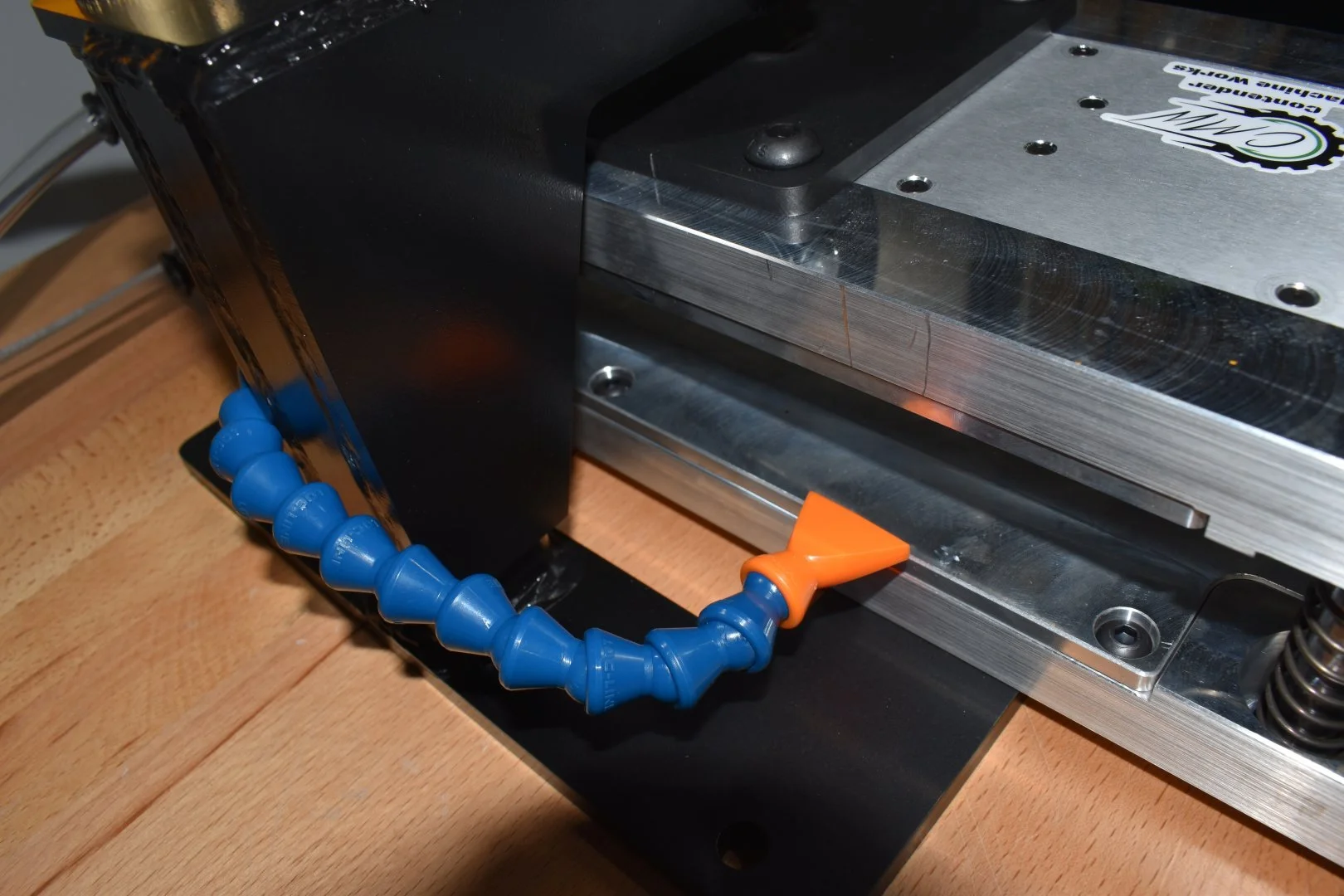

The dual air nozzles can be positioned to direct an air blast in between the clamped plates to help cool the blade faster. A simple ball valve provides easy and fast operation of the air blast.

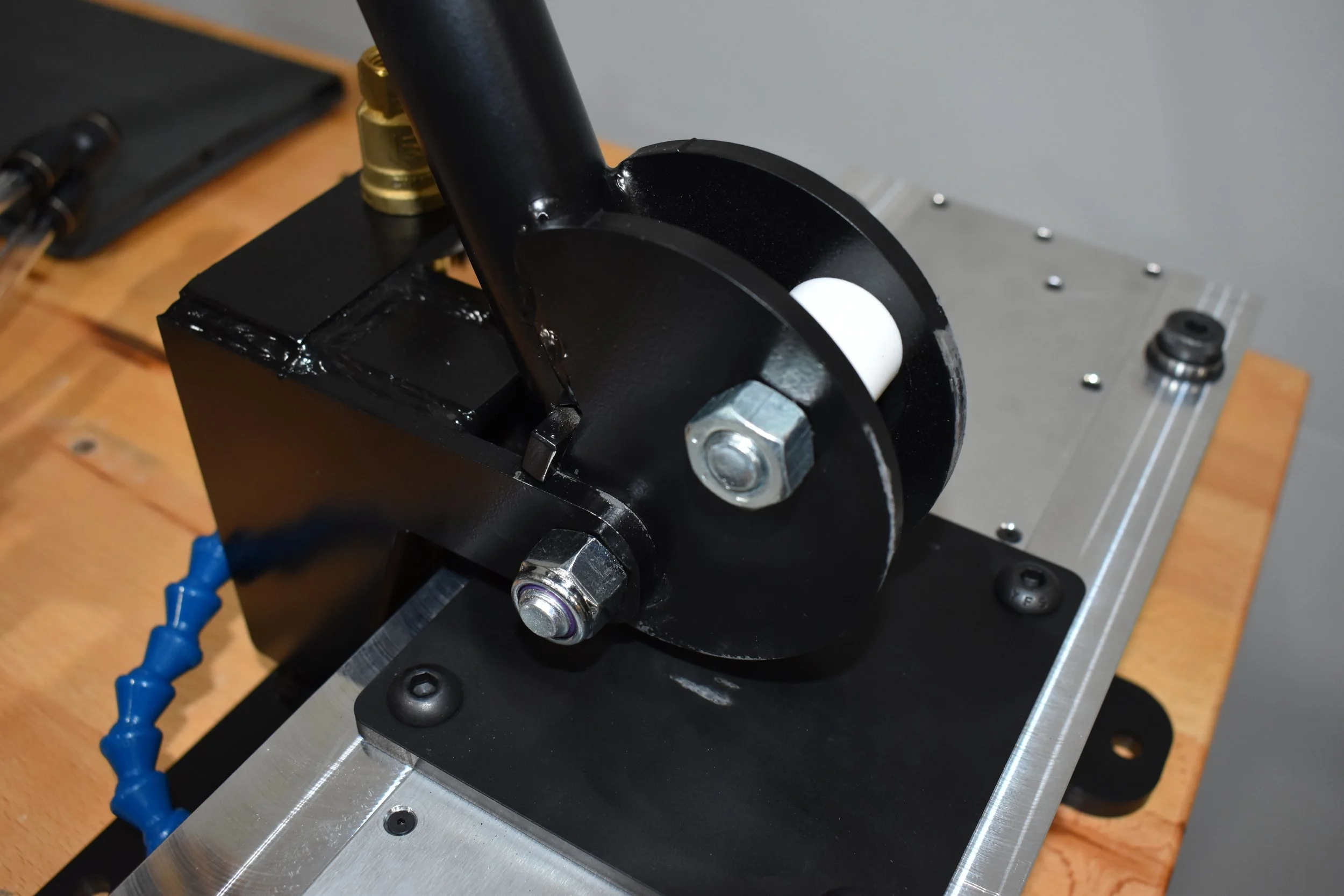

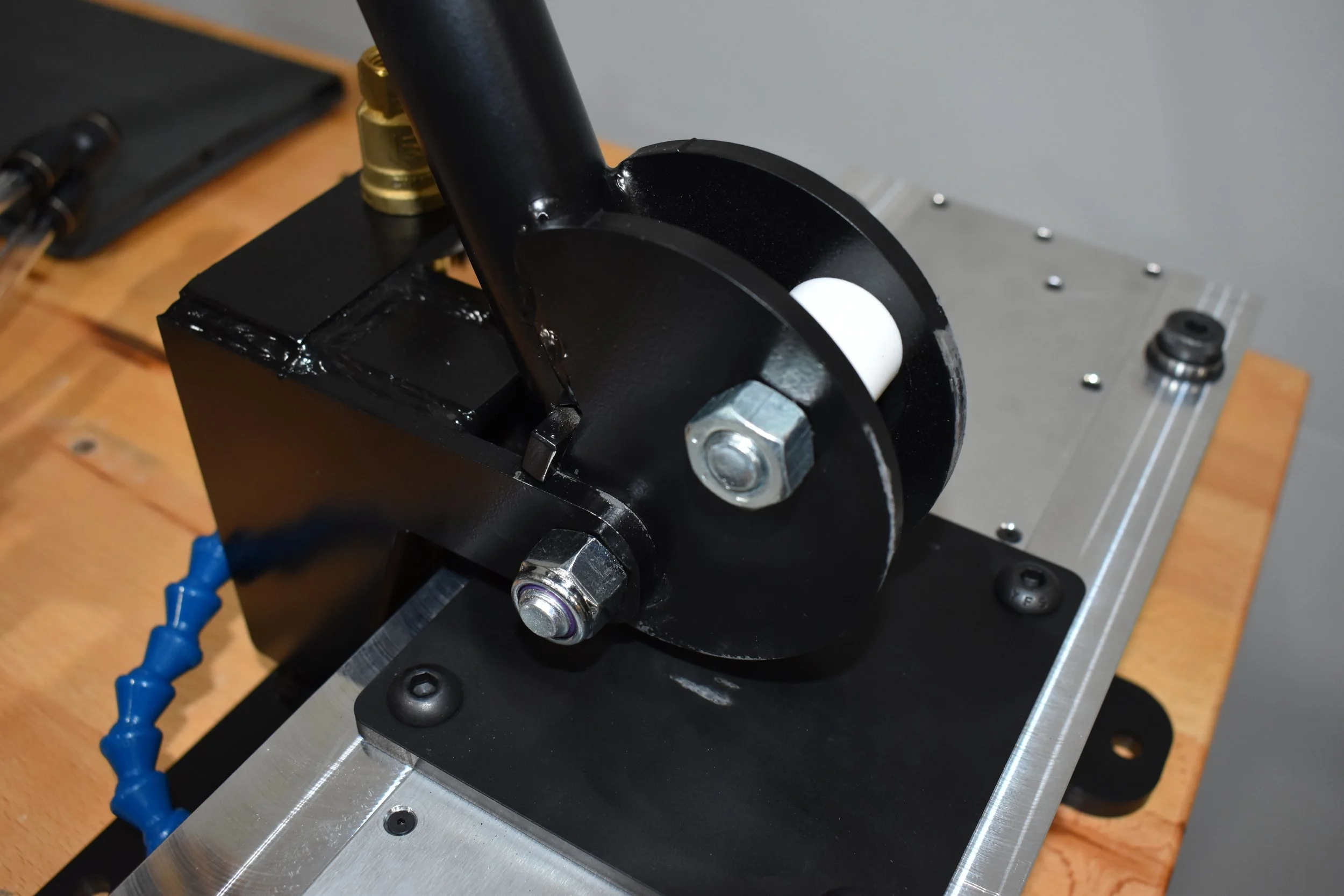

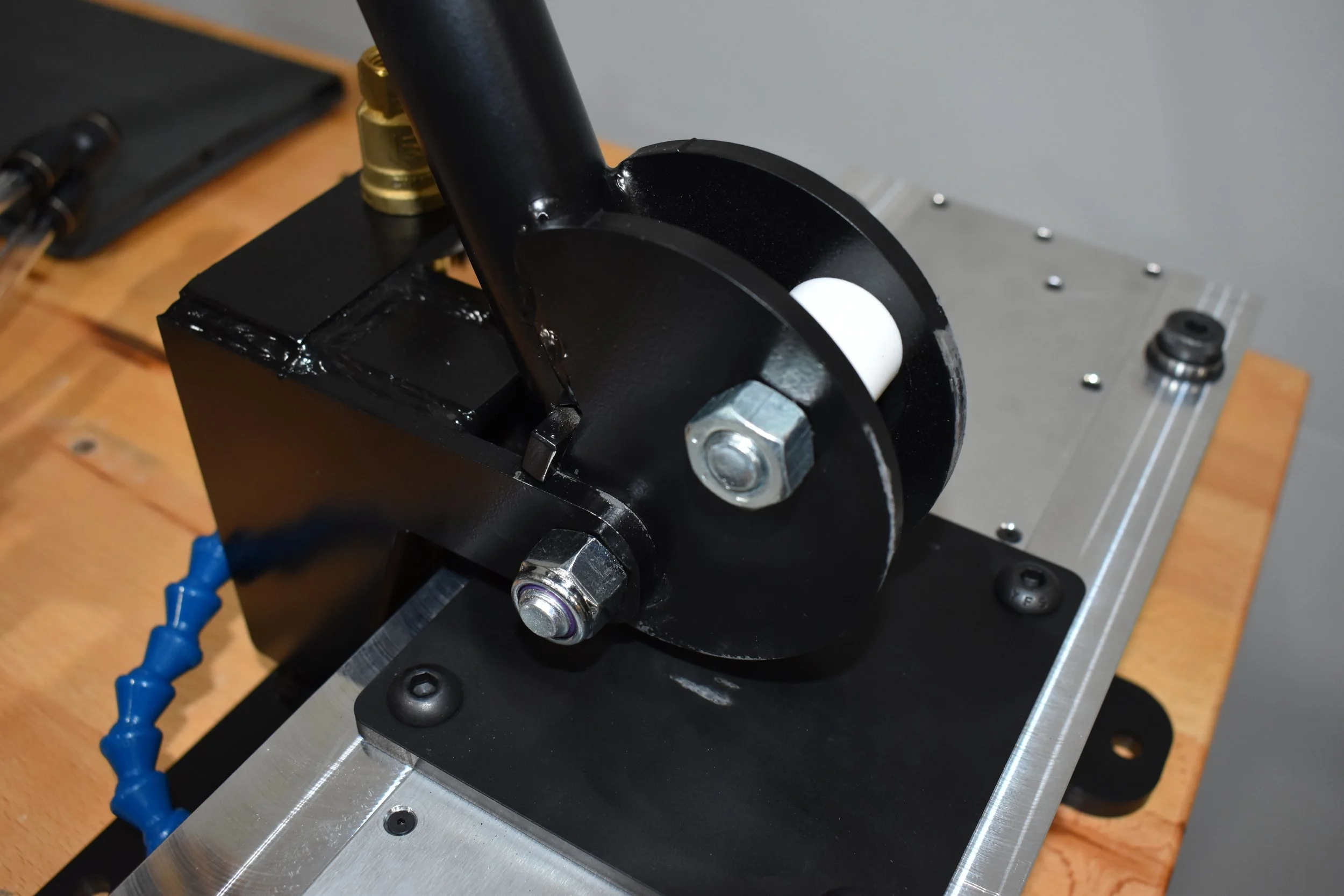

The cam over clamping system provides fast and heavy clamping of the blade. Speed is important for a consistent and accurate heat treating process. Testing has shown the clamp pressure to easily exceed 1000 psi of force.

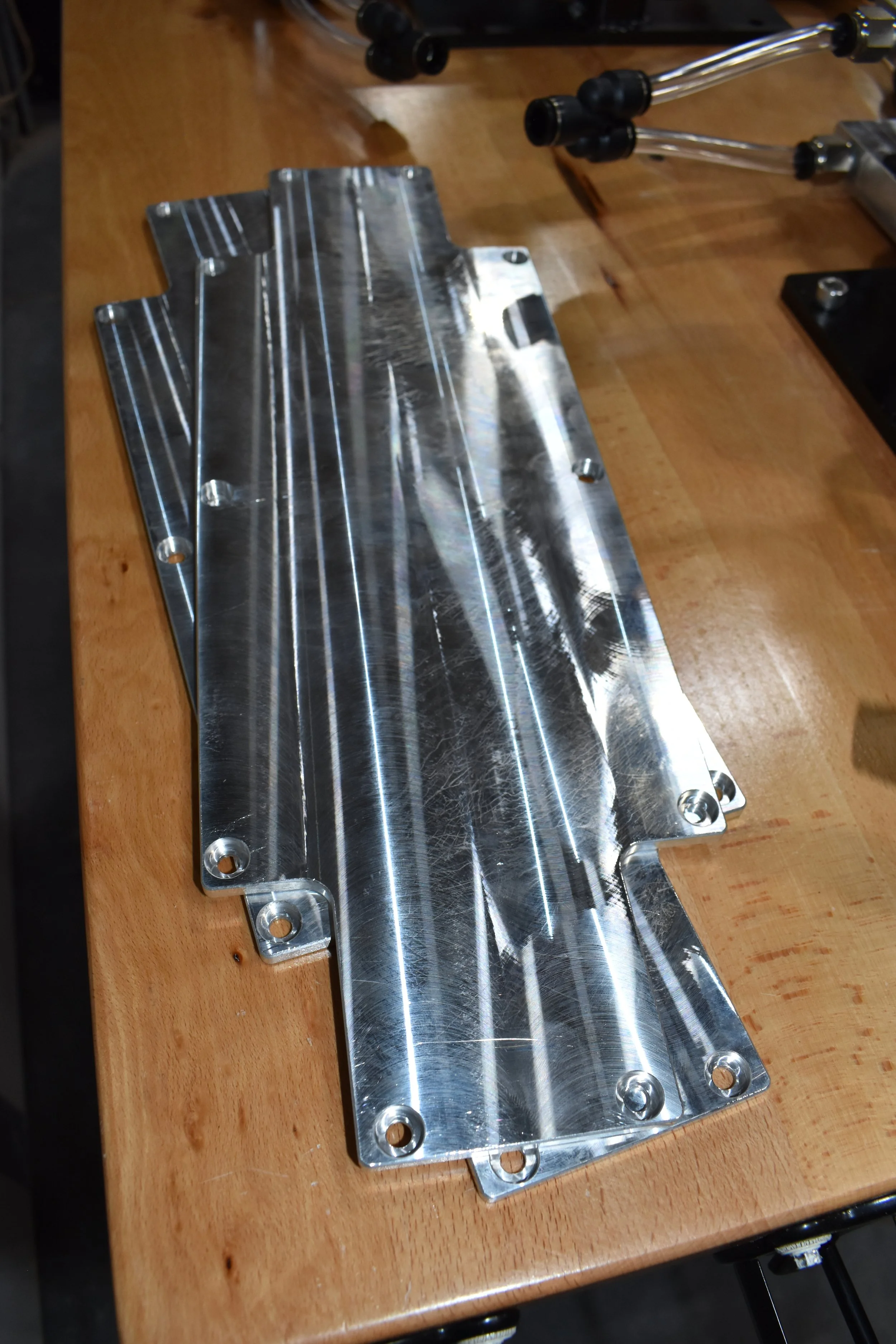

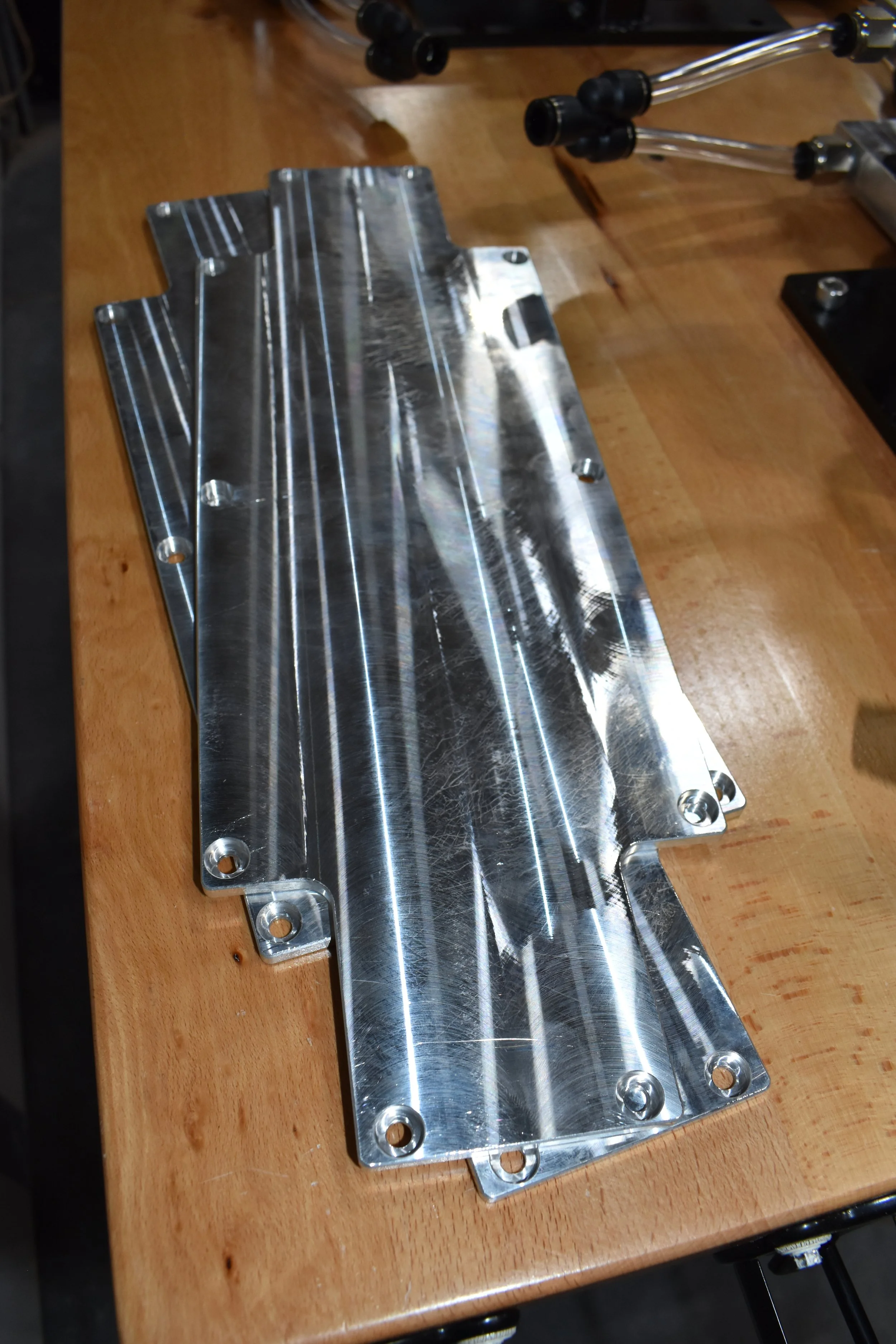

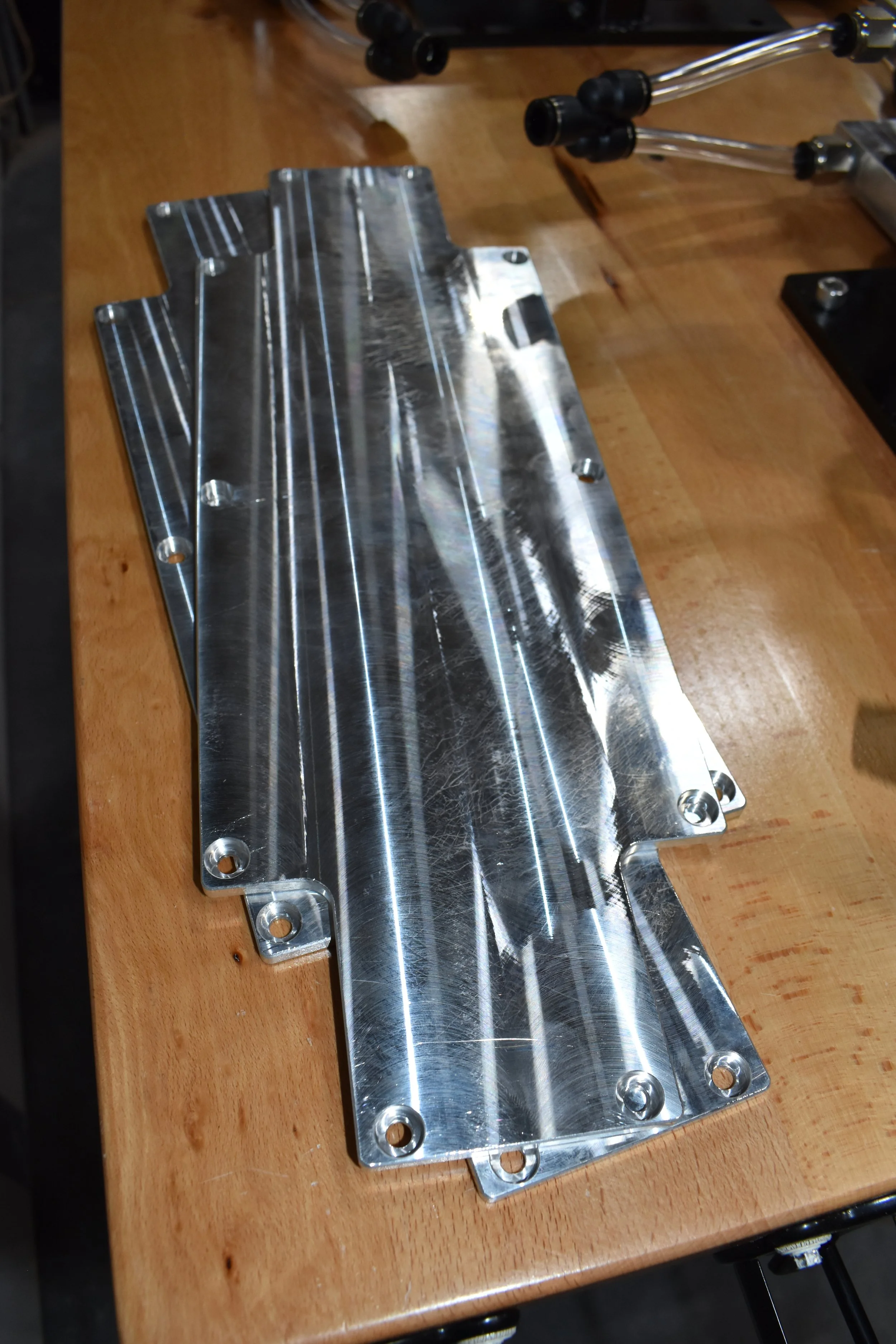

The 18 inch plates now have a sub plate option. These sub plates are bolted into each main plate and are meant to be replaced if they become damaged or worn out. This is a more cost effective solution in the long run if you plan to use them heavily. The sub plate version comes with one set of plates installed. Replacements are sold by the pair.

A small, submersible pond pump is used to pump water or antifreeze through the plates. Sold here.

Quick connect fittings for use with 1/2 inch hose are included. The same pump system used on our magnetic heatsinks can be used with these plates by simply unplugging the inlet hose from the heatsink and plugging it into the quench plate press.

8 feet of both inlet and outlet hose is included.

The Contender Machine Works quench plate press is the easy solution for heat treating your air hardening steels. The press features machined 1 inch thick aluminum plates that ride on linear bearings for a smooth and accurate plate quench.

Both 15.5- and 18-inch-long plates available. Please inquire about custom plate sizes.

Water jackets running through both plates provide constant cooling to keep the plates a consistent temperature. This is key to a consistent and accurate quench when heat treating a batch of blades.

The dual air nozzles can be positioned to direct an air blast in between the clamped plates to help cool the blade faster. A simple ball valve provides easy and fast operation of the air blast.

The cam over clamping system provides fast and heavy clamping of the blade. Speed is important for a consistent and accurate heat treating process. Testing has shown the clamp pressure to easily exceed 1000 psi of force.

The 18 inch plates now have a sub plate option. These sub plates are bolted into each main plate and are meant to be replaced if they become damaged or worn out. This is a more cost effective solution in the long run if you plan to use them heavily. The sub plate version comes with one set of plates installed. Replacements are sold by the pair.

A small, submersible pond pump is used to pump water or antifreeze through the plates. Sold here.

Quick connect fittings for use with 1/2 inch hose are included. The same pump system used on our magnetic heatsinks can be used with these plates by simply unplugging the inlet hose from the heatsink and plugging it into the quench plate press.

8 feet of both inlet and outlet hose is included.