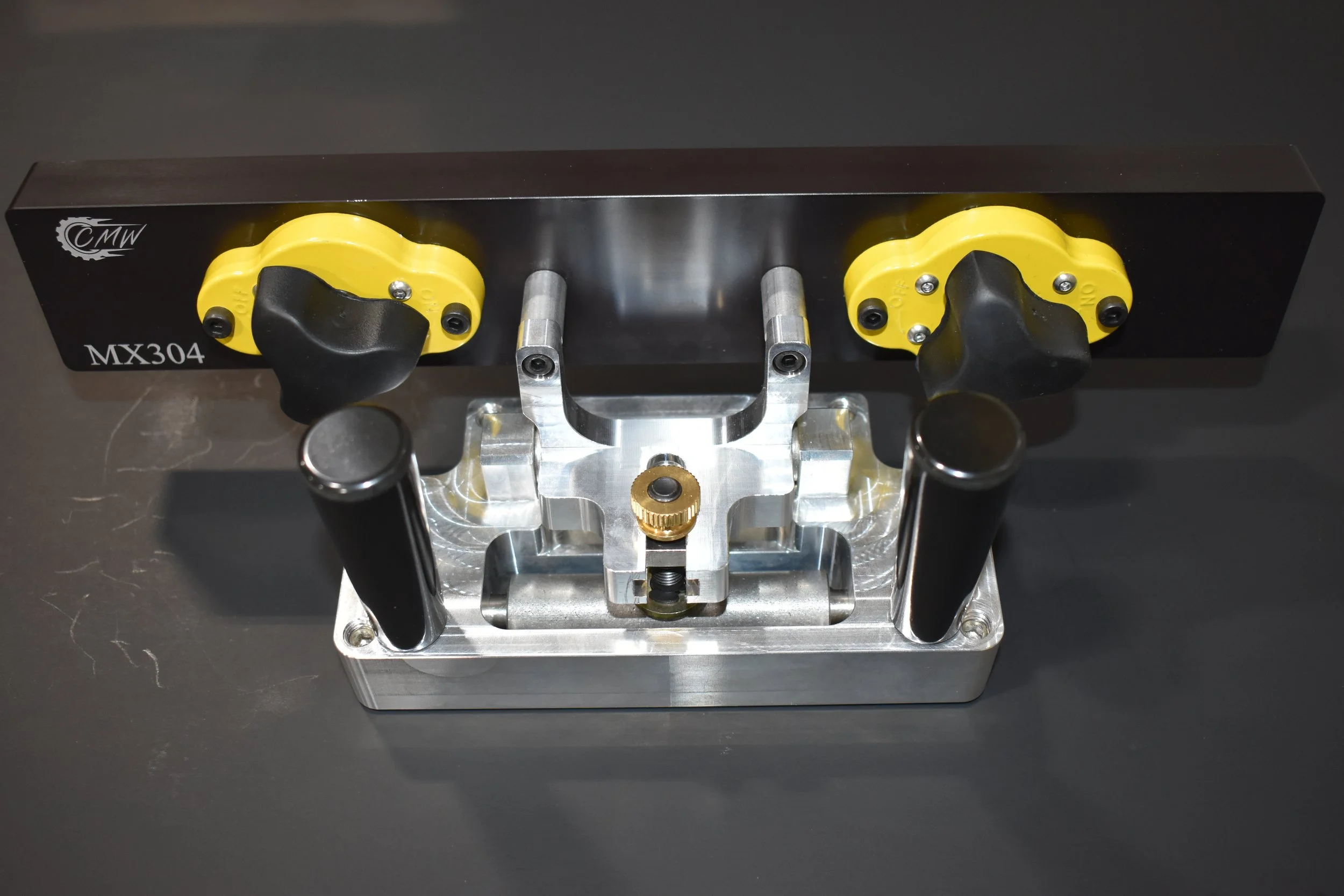

Designed to be sturdy and accurate this bevel grinding jig will hold its position and create consistent bevels. Features billet machined aluminum frame with mostly stainless fasteners.

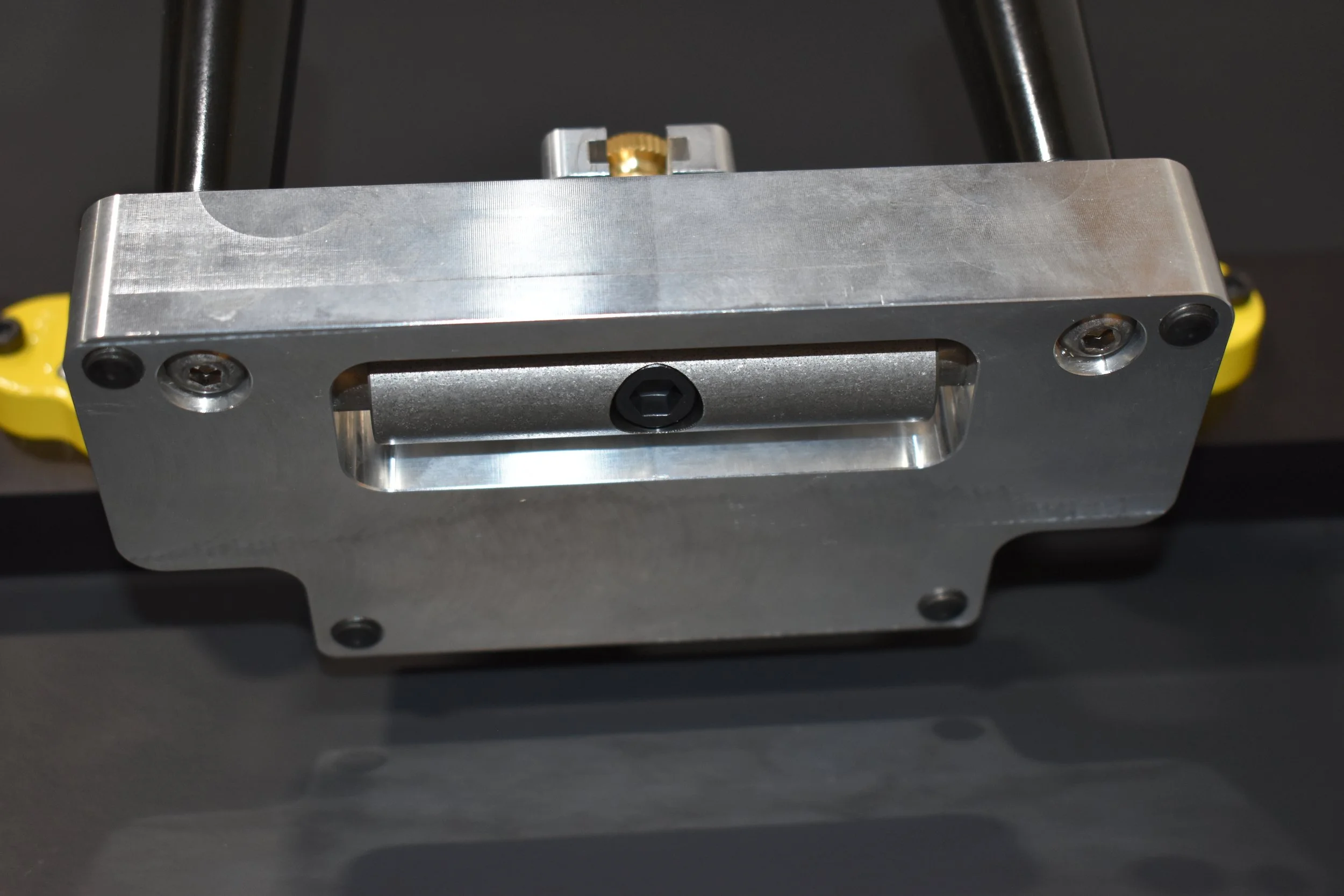

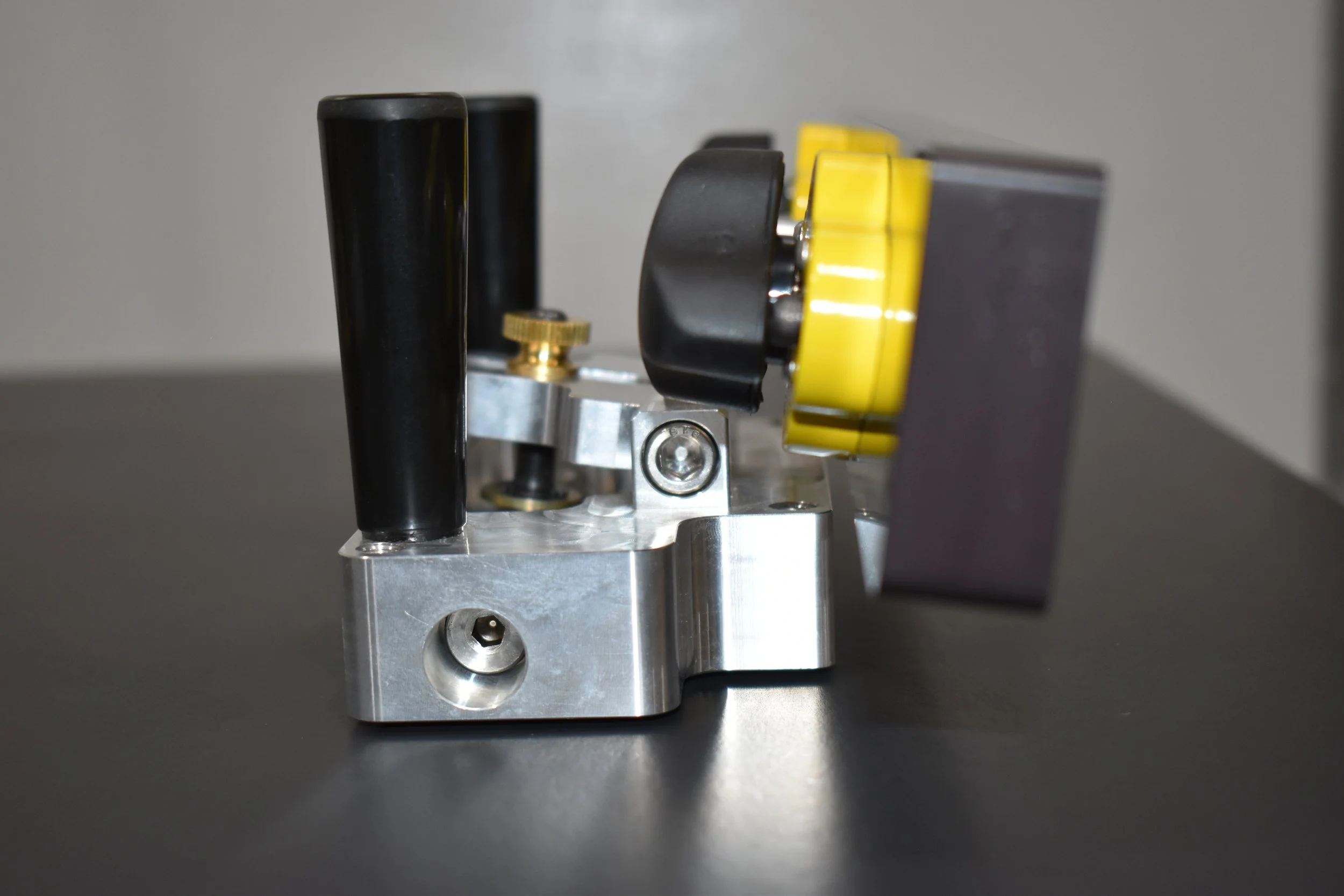

The jig rides on four slide feet that allow it to be adjusted to not rock on any grinding rest and are easily and cheaply replaced when they finally wear down. These four small points of contact allow this jig to easily slide over the grinding rest even when covered in grinding dust. A fine thread bolt accessed from the bottom of the jig allows the angle to be precisely adjusted and tweaked to produce a perfect bevel. The stainless steel jam nut locks the angle of the tool in so it has absolutely no slop. This jig remains rock solid and will repeat blade after blade.

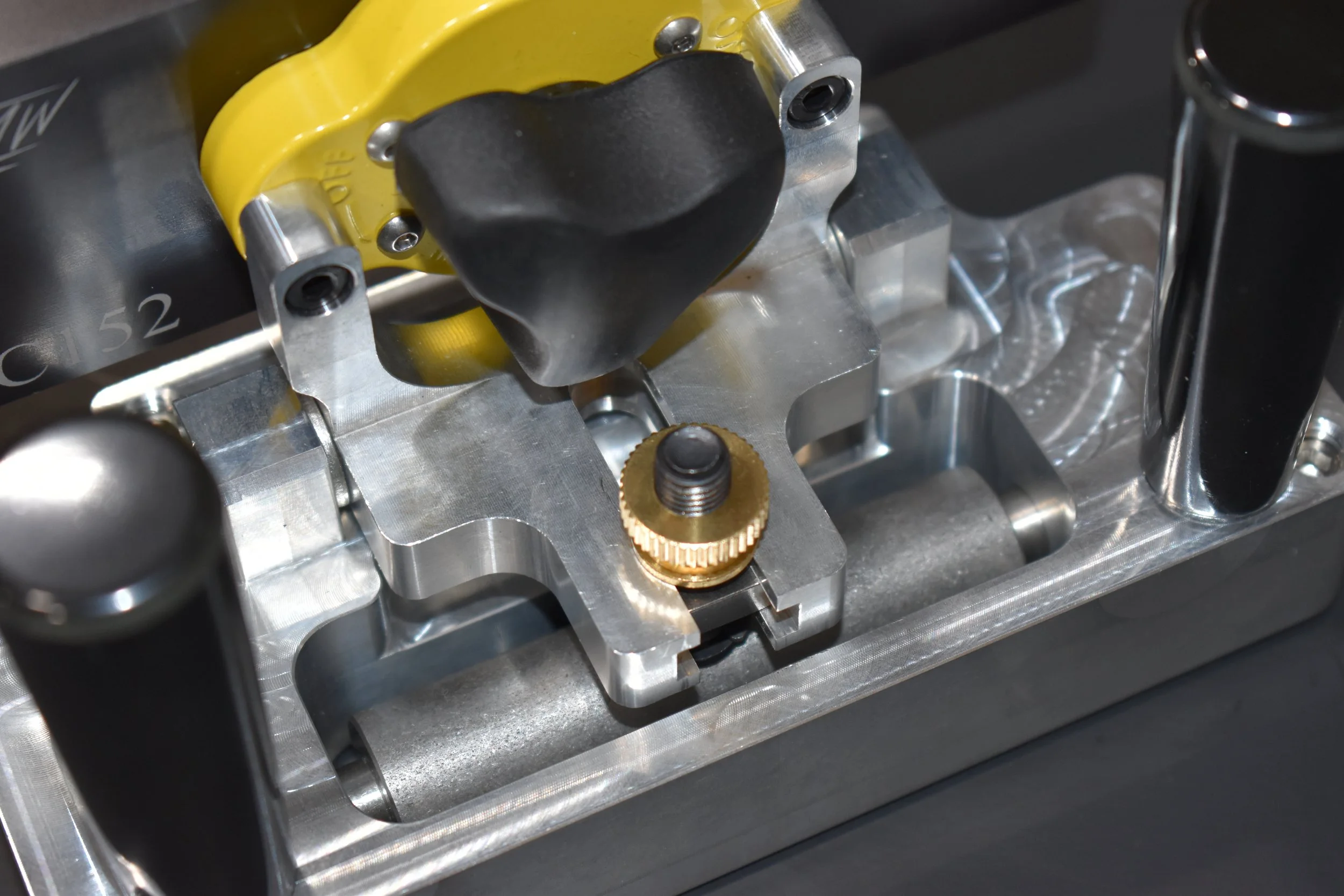

The integrated Magchuck of your choosing allows the blades to be removed and replaced with just the turn of the knob. The dowels can be mirrored from one side to the other when the blade is flipped allowing for an exact mirroring of the blade. This allows for consistent bevels from one side of the blade to the other. The base of the jig measures 6x4 inches.

Each jig comes with 10 dowels, extra hardware and a T-handle Allen wrench for adjusting the angle.